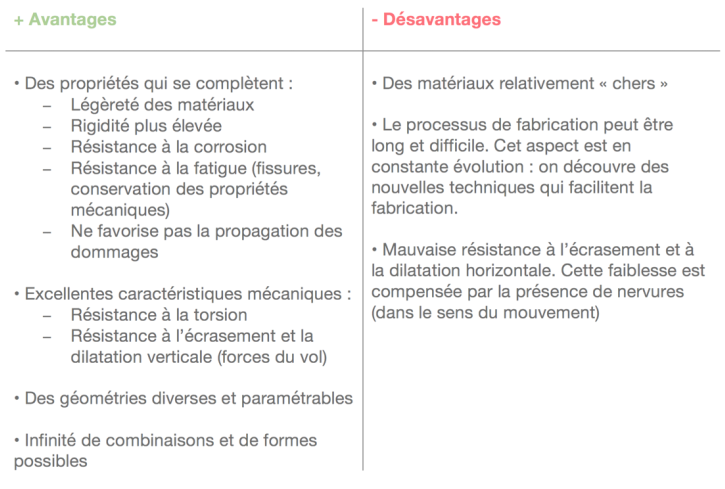

Visit composite materials are widely used in the automotive, aerospace and marine industries, thanks to their lightness and strength. However, they also present disadvantages such as the high cost and difficulty of repairing them in the event of damage. In this article, we take a closer look at advantages and disadvantages composite materials to help you understand whether these materials are suitable for your project.

Composite materials: between performance and limits

Composite materials are increasingly used in many sectors, including the automotive, aeronautics and even construction industries. These materials offer high performance in terms of mechanical strength, lightness and durability. However, like all materials, they also present limitations and challenges. For example, their cost is often higher than that of traditional materials, their manufacture can be complex and they can be more difficult to recycle. As a news site dealing with topics relating to innovation, it is important to keep abreast of advances and developments in this field, as well as to raise public awareness of the benefits and limitations of composite materials. Composite materials are not a universal solution, but they do offer interesting performance features for certain applications. It's also important to think about the environmental impact of their use, and to promote initiatives to improve their recycling and reuse. Ultimately, as with any topic, it's essential to provide balanced and informative coverage of composite materials, their opportunities and challenges, to the readers of our news site.

The materials that surround us - L'Esprit Sorcier

[arve url="https://www.youtube.com/embed/_GV35WRH23E "/]

[How does it work?] What are the different families of materials around us?

[arve url="https://www.youtube.com/embed/VevQyq3kzGQ "/]

What are the disadvantages of composite materials?

Visit composite materials are widely used in the automotive, aerospace and marine industries, thanks to their lightness, strength and insulating properties. However, they also present disadvantages important.

First and foremost, composite materials are expensive to produce. Their manufacture requires sophisticated and complex processes, as well as the use of costly raw materials.

What's more, these materials can be difficult to recycle. The various components that make them up cannot be easily separated, which can lead to major environmental problems.

In addition, composite materials are shock-sensitive. Although they are very strong, they can crack or break under the impact of high force. This can be particularly dangerous in industries where safety is paramount.

Finally, composite materials can be difficult to repair in the event of damage. Repair procedures are often complicated and costly, and may require specialized skills that are not always available.

Despite these disadvantages, composite materials continue to be widely used due to their unique advantages. However, it is important to take these disadvantages into account when using them, and to seek solutions to minimize their impact on the environment and safety.

What are the benefits of composite materials?

Composite materials offer several advantages over traditional materials such as metal, wood or concrete. Firstly, their low weight makes them a very attractive option for industries such as aerospace and automotive that are looking to reduce the weight of their products to improve performance and fuel consumption. What's more, they have a high resistance to tensile and compressive strength, making them ideal for structures that need to be both strong and lightweight.

Visit composite materials are also highly resistant to corrosion and chemicals, making them suitable for use in marine and aggressive industrial environments. They can be molded into any shape and therefore offer a high degree of flexibility. design flexibilityThis enables the creation of innovative and aesthetically pleasing products. What's more, they have a good thermal and acoustic insulationwhich makes them suitable for civil engineering and construction applications.

Finally, the composite materials are durable and long-lasting, making them a cost-effective long-term option for businesses. However, it's important to note that composite materials require special expertise to manufacture and use correctly, and their disposal can pose environmental challenges.

What are the benefits and drawbacks of carbon?

The benefits and drawbacks of carbon

Carbon is a chemical element present in all forms of life on Earth. It is also used in a wide range of industries to manufacture products such as tires, plastics, cosmetics and even medicines. However, carbon has both advantages and disadvantages.

The benefits of carbon

- Carbon is essential to plant life and growth. Plants absorb carbon dioxide from the air and use the sun's energy to transform it into organic matter through photosynthesis. This process is vital for environmental balance and the survival of many species.

- Carbon is used in many industrial sectors to manufacture strong, resistant products. For example, carbon fiber is increasingly used in the manufacture of cars and aircraft to reduce weight while maintaining strength.

- Carbon is also used to produce energy. Coal is one of the world's main sources of electricity, although it is increasingly being replaced by renewable energy sources.

The disadvantages of carbon

- Excessive use of fossil fuels such as coal, oil and natural gas has negative effects on the environment. Burning these fuels releases carbon dioxide into the atmosphere, contributing to global warming and air pollution.

- Carbon emissions can also have negative effects on human health. Air pollution from fossil fuels can cause respiratory and cardiovascular problems.

- The extraction of certain forms of carbon, such as coal, can also have negative effects on the environment. Mining can damage ecosystems and destroy natural habitats.

In conclusion, carbon is an essential element for life on Earth and for modern industry. However, excessive use of fossil fuels has negative effects on the environment and human health. It is therefore important to look for solutions to reduce our dependence on fossil fuels and promote renewable energy sources.

What is the environmental impact of composites?

Composites have a significant environmental impact, not least because they are difficult to recycle. Composites are materials that result from a mixture of several different components, such as carbon or glass fibers, and synthetic resins. These materials are used in many sectors, including boat, aircraft and wind turbine construction, as well as in the automotive and sports equipment industries.

The main problem with composites is that they are very difficult to recycle. The different layers of material that make them up are often permanently bonded together, which means that the process of separating the different materials is highly complex, costly and energy-intensive. What's more, composites often contain synthetic resins that are non-biodegradable and can release hazardous chemicals into the environment as they break down.

Despite thisThere are also a number of initiatives aimed at improving the durability of composites. Some companies are seeking to develop composites that are more easily recyclable, using biosourced or biodegradable resins, for example. Others are trying to reduce the environmental impact of composites by optimizing production processes, using fewer materials or working on the design of finished products to make them more durable and repairable.

HoweverHowever, there is still much to be done to reduce the environmental impact of composites. It is important that companies using these materials seek to develop more sustainable solutions, and that consumers are aware of the impact of their purchasing choices on the environment.

What are the advantages and disadvantages of composite materials compared with traditional materials?

The advantages and disadvantages of composite materials over traditional materials

Composite materials have gained in popularity in many industries in recent years. The main advantages of composite materials include their light weight, high corrosion resistance, the ability to be molded into complex shapes, and their thermal and electrical insulating properties. In addition, composite materials can be manufactured to precise specifications, making them a popular choice for aerospace applications.

However, composite materials also have their drawbacks. Firstly, they are more expensive than traditional materials such as wood, steel and concrete. In addition, repairing composite parts can be difficult and costly, as they are often damaged below the surface. In addition, the fire resistance and durability of composite materials are often inferior to those of traditional materials.

In conclusion, it is important for engineers and builders to weigh up the advantages and disadvantages of composite materials versus traditional materials, in order to choose the most appropriate material for their specific application.

What are the advantages of composite materials for the design of lightweight, high-strength parts?

Composite materials offer several benefits for the design of lightweight, high-strength parts. Firstly, they are made from two or more different materials, enabling them to benefit from the properties of each material used. In addition, the suit of these materials offers resistance for a relatively low weight.

Composites are also very corrosion-resistantThis makes them ideal for use in harsh or water-exposed environments. In addition, they are highly shock-resistant and can therefore be used in applications where safety is paramount.

Last but not least, composite materials are also hoses in terms of design. They can be molded into complex shapes, enabling designers to create parts that would be impossible with traditional materials. This also offers great potential for weight optimization and lower costs thanks to mass production.

In short, composite materials offer numerous advantages for the design of lightweight, strong parts, making them particularly suitable for use in industries such as aerospace, automotive and shipbuilding.

How can composite materials present disadvantages during manufacture and recycling?

Composite materials are often used in industry for their lightness and strength. However, their manufacture can have its drawbacks. Firstly, the manufacturing process is more complex than that of traditional materials, which can lead to higher costs. What's more, some composite materials require the use of chemicals that are harmful to the environment and workers' health.

Recycling composite materials, it can also pose problems. The different materials that make up composite material have to be separated before they can be recycled, which can be difficult and costly. In addition, composite materials can be difficult to recycle due to their complex structure, meaning that they may end up in landfill rather than being recycled.

These disadvantages need to be taken into account in the manufacture and end-of-life management of composite materials. It is important to find ways of reducing the use of harmful chemicals and facilitating the recycling of composite materials to minimize their impact on the environment.

In conclusion, the composite materials offer significant advantages in a number of fields, including aeronautics, automotive and naval engineering. Their lightnesstheir resistance shock resistance and durability make them ideal allies for many industrial applications. However, they also have some disadvantages to consider, notably their high costtheir specific maintenance and their recycling difficulties. It is therefore important to assess needs and constraints before deciding to use composite materials in a given project.