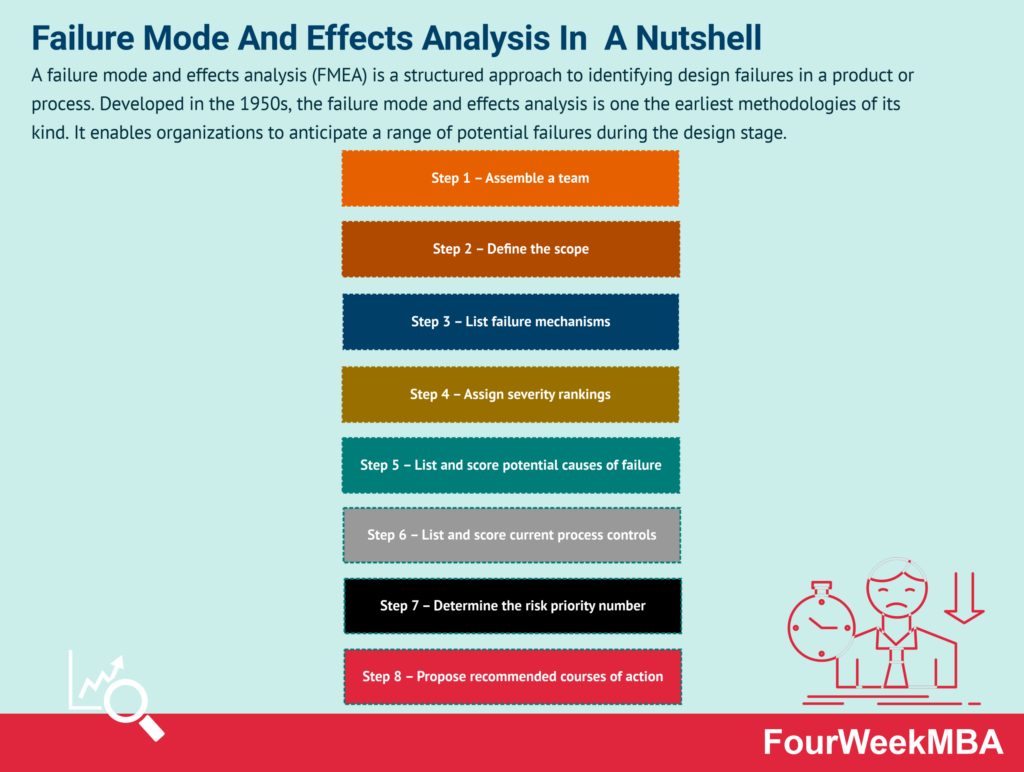

FMEA (Failure Mode, Effect and Criticality Analysis) is a quality management tool widely used in industry. This article examines the advantages major of FMECA, such as improving product safety and reducing failure-related costs. However, it also highlights some drawbacks such as the complexity of implementation and the time required to collect data.

You're ruining your semester with these 3 ERRORS 😓

[arve url="https://www.youtube.com/embed/GexQzqRkjvU "/]

Why choose the FMECA method?

The FMEA method (Failure Modes, Effects and Criticality Analysis) is an approach widely used in industry to assess the risks associated with a process or product. In the context of a news site, it is essential to use this method to guarantee the reliability and quality of the information provided to readers.

Here are a few reasons why you should choose the FMECA method:

1. Identification of potential failures : The FMECA method is used to identify the various faults that can occur in the news creation and distribution process. These can include errors in news gathering, technical problems with the website or editorial errors.

2. Assessing the impact of failures : Once failures have been identified, the FMECA method can be used to assess their potential impact on news quality. This can include consequences such as erroneous information, publication delays or loss of site credibility.

3. Estimating the criticality of failures : The FMECA method also makes it possible to assess the criticality of the various failures identified. This helps to prioritize corrective actions and implement preventive measures according to the importance of each failure.

4. Continuous improvement : By using the FMEA method, you can identify recurring problems and implement continuous improvement actions to avoid their recurrence. This helps guarantee consistent news quality and maintain reader satisfaction.

In short, the FMECA method is essential for ensuring the reliability and quality of the information provided by a news site. It enables potential failures to be identified, their impact and criticality to be assessed, and preventive and corrective actions to be taken to continually improve the news creation and distribution process.

What is the purpose of FMECA?

FMEA, or Failure Modes, Effects and Criticality Analysis, is a method used in industrial risk management. Its main aim is to identify potential system failures, assess their impact and determine their criticality. FMEA thus enables us to anticipate and prevent problems that may arise in a process or product. It is widely used in many sectors, including the automotive, aeronautics and pharmaceutical industries.

Failure mode analysis is to identify all possible causes of system failure, whether internal (such as mechanical failure) or external (such as human error). Effects analysis then enables us to assess the consequences of these failures on the system, whether immediate or long-term. Last but not least, criticality assessment consists of assigning a severity rating to each failure, based on its potential impact.

FMECA enables companies to take preventive and corrective measures to minimize the risks associated with failures, and to ensure system reliability. This method helps to improve product or process quality, reduce maintenance costs and enhance customer satisfaction.

In short, FMECA is an essential tool in industrial risk management, enabling potential system failures to be identified and assessed, in order to prevent them and guarantee the quality and reliability of products or processes.

What's the difference between product FMECA and process FMECA?

Product FMECA and Process FMECA are both risk analysis methods used in industry to guarantee the quality and safety of products and processes. However, they focus on different aspects.

Product FMECA aims to assess the risks associated with the design and manufacture of a product. It involves identifying all possible product failure modes, as well as the causes and consequences of these failures. The aim is to anticipate and prevent potential problems in order to improve product reliability and durability.

Process FMEAOn the other hand, risk management focuses on assessing the risks associated with the various stages of the production or service delivery process. It aims to identify potential failures that could occur during the various stages of the process, such as human error, equipment failure, delays or communication errors. The main aim is to optimize the process, minimizing risks and guaranteeing efficient, high-quality production.

In short, Product FMECA focuses on the risks associated with the product itself, while Process FMECA looks at the risks associated with production or service delivery stages. The two methods are complementary and can be used together to ensure the best possible quality.

How do you make a good FMECA?

To carry out a good FMEA (Failure Mode, Effect and Criticality Analysis) in the context of a news site, it is important to follow a rigorous methodology. Here are the key steps to follow:

1. System identification: Start by clearly defining the system you want to analyze. In this case, it's the news site itself.

2. List of components: Make a complete list of all news site components, such as server, database, publishing modules, etc.

3. Identifying potential failures: For each component, identify all the potential failures that could occur. For example, a server failure could lead to site unavailability.

4. Estimated consequences: Evaluate the consequences of each potential failure. For example, prolonged site unavailability could result in a loss of traffic and advertising revenue.

5. Criticality assessment: Determine the criticality of each failure by combining the probability of occurrence with the associated consequences. For example, a failure with a high probability of occurrence and severe consequences will be considered more critical.

6. Definition of preventive measures: Identify appropriate preventive actions to reduce the probability of critical failures occurring and mitigate their consequences. For example, implement regular site backups and security measures to avoid computer attacks.

7. Follow-up and updates: Make sure you regularly monitor the effectiveness of the preventive measures you have implemented, and update the FMECA in line with any changes in the system.

By following these steps, you will be able to carry out an effective FMECA for your news site, enabling you to identify potential failures and take the necessary measures to prevent or manage them.

In conclusion, Failure Mode, Effect and Criticality Analysis (FMEA) has both strong advantages and disadvantages.

On one side, FMECA helps to identify and prevent potential failures in a system or process. It enables problems and associated risks to be anticipated, enabling effective preventive measures to be adopted. In addition, it provides a better understanding of the causes of failure, enabling targeted corrective action to be taken.

On the other hand, FMECA can be a cumbersome and complex process, especially in large organizations. It requires extensive data collection, meticulous analysis and the ability to anticipate risks. What's more, some failures can be difficult to predict, and FMECA alone does not guarantee total elimination of risk.

It is therefore essential to consider all aspects before deciding to implement an FMECA. A thorough assessment of the potential benefits and obstacles encountered in implementing this method is necessary to obtain the best results.

In short, FMECA remains a useful tool for preventing failures and improving the quality of systems and processes. However, its use must be adapted and proportioned to the specific context of each organization, in order to maximize its benefits while minimizing its drawbacks.