What are the advantages and disadvantages of pressure sensors?

Pressure sensors are devices that measure the pressure of a fluid or gas. They are used in many fields, including automotive, aerospace, medicine and many others. The advantages of pressure sensors are numerous. Firstly, they offer high accuracy in pressure measurement, which is essential in certain critical applications, such as aircraft engines.

In addition, pressure sensors can be small and lightweight, making them easy to integrate into portable or mobile devices. Finally, they can be used to measure pressure in hostile environments, such as oil drilling or submarines.

However, there are also disadvantages to using pressure sensors. Firstly, they can be sensitive to temperature variation, which can affect measurement accuracy. In addition, they can be expensive, especially if used in specific applications. Finally, pressure sensors often require regular calibration to maintain their accuracy, which can be tedious.

In short, pressure sensors are useful devices in many fields, offering high accuracy and flexibility of use. However, they also have their drawbacks in terms of cost and regular maintenance.

Accuracy of pressure transducers | You must be careful not to make these 3 mistakes!

[arve url="https://www.youtube.com/embed/dChljWrjCJk "/]

The pressure sensor

[arve url="https://www.youtube.com/embed/G2dyT1JKp-Y "/]

What is the function of a pressure sensor?

A pressure transducer is an electronic device used to measure the pressure of a fluid or gas. It is often used in industrial applications to monitor air, water or oil pressure in hydraulic or pneumatic systems. The data collected by this sensor can be used to ensure the safe and efficient operation of machines, equipment and processes. The information provided by the sensor is transmitted to a computer or control system, which can make decisions based on the pressure changes detected. Pressure sensors are also used in smaller devices, such as cell phones, to measure atmospheric pressure and provide weather information.

Why replace the pressure sensor?

The reason for replacing the pressure sensor may vary depending on the situation. In the context of new cars, the main reason could be that the pressure sensor is faulty and not supplying the correct information to the engine management system. This can lead to reduced performance and increased fuel consumption. In some cases, it can also lead to a complete engine stoppage. So it's important to replace the faulty sensor quickly to prevent further damage to the vehicle and ensure safe driving.

How can I tell if the pressure sensor is faulty?

The following steps can be taken to determine whether the pressure sensor is faulty:

1. Check the error code: If the vehicle's engine light comes on, this may indicate a problem with the pressure sensor. In this case, you can use a code scanner to check which specific code has been displayed. This code may provide information on why the light is on.

2. Check engine performance: If the pressure sensor is faulty, this can lead to reduced engine performance. You can therefore check if the engine has difficulty accelerating or if you are experiencing starting problems.

3. Check fuel consumption: A faulty pressure sensor can also lead to higher-than-normal fuel consumption. You can therefore check whether you need to fill the tank more often than before.

If you notice any of these symptoms, the pressure sensor is probably defective. We recommend that you replace the pressure sensor with a new one, and have it checked by a professional mechanic before getting back on the road.

What criteria should I take into account when choosing a pressure sensor?

The criteria to be taken into account when choosing a pressure transducer vary according to the application and specific requirements. Here are a few things to consider when selecting a pressure transducer:

1. Pressure type : There are different types of pressure, such as absolute pressure, relative pressure, differential pressure and so on. The choice of sensor depends on the pressure to be measured.

2. Measuring range : The measuring range is the pressure range the sensor can measure. Choose a sensor that covers the pressure range required for your application.

3. Precision: Precision is a measure of the sensor's accuracy. The higher the precision, the more reliable the data collected.

4. Temperature : Some sensors are temperature-sensitive and can give erroneous readings in the event of temperature fluctuations. It's important to choose a sensor that can operate effectively under the specific temperature conditions of your application.

5. Size and shape : The size and shape of the sensor are important in determining where and how it can be installed.

6. Durability : If the sensor is to be used in harsh conditions, it must be able to withstand vibration, humidity, shock, etc.

In conclusion, the choice of pressure transducer will depend on the specific requirements of your application and its context of use.

What are the advantages and disadvantages of pressure sensors for measuring tire pressure?

Advantages of pressure sensors for measuring tire pressure :

Pressure sensors provide precise, real-time measurement of tire pressure, ensuring greater safety on the road. They also help prevent accidents caused by under-inflated or over-inflated tires by alerting the driver if tire pressure exceeds or falls below a certain level. What's more, they can help save fuel by maintaining optimum tire pressure, which can also help reduce tire wear.

Disadvantages of pressure sensors for measuring tire pressure :

The main disadvantage of pressure sensors is that they can be costly to install and maintain. In addition, some models may be subject to electromagnetic interference or malfunction in extreme weather conditions. Finally, some drivers may be tempted to ignore tire pressure alerts, which can jeopardize their safety and that of other road users.

What are the advantages and disadvantages of absolute pressure sensors compared with relative pressure sensors?

Visit absolute pressure transducers measure pressure relative to an absolute vacuum, while the relative pressure transducers measure pressure in relation to atmospheric pressure.

The advantage of absolute pressure transducers is that they are more accurate and can be used to measure pressure in environments where atmospheric pressure can vary, such as aircraft and high-altitude applications. They are also useful for measuring pressure in vacuum or low-pressure conditions.

The disadvantage of absolute pressure transducers is that they are more expensive than relative pressure sensors, and require a reference to absolute vacuum. In addition, they are not suitable for applications where atmospheric pressure is an important factor to consider, such as measuring atmospheric pressure itself, or measuring small pressure variations in environments with stable atmospheric pressure.

In conclusion, the choice between absolute and relative pressure transducers will depend on the specific needs of the application and the environmental conditions in which they will be used.

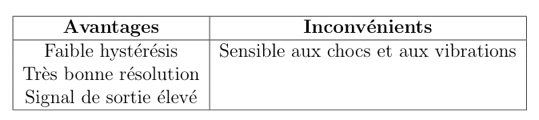

What are the advantages and disadvantages of piezoresistive pressure sensors compared with capacitive pressure sensors?

Piezoresistive pressure transducers have several advantages over capacitive pressure sensors. Firstly, they are less expensive to produce, making them more accessible for consumer applications such as wearable devices or sports equipment. In addition, they are more robust and less sensitive to electromagnetic interference, making them suitable for noisy industrial environments.

However, piezoresistive pressure transducers also have their drawbacks. They are prone to drift and their accuracy decreases over time, requiring regular calibration to maintain acceptable accuracy. They are also more sensitive to temperature changes, which can lead to measurement errors if temperature is not taken into account.

On the other hand capacitive pressure transducers offer greater accuracy and higher resolution, making them suitable for applications where precision is paramount. They do not require regular calibration and are less sensitive to temperature variations. However, they are more expensive to produce and more sensitive to electromagnetic interference.

In short, both types of sensor have their strengths and weaknesses, and their choice will depend on application specifications and accuracy/cost requirements.

In conclusion, the pressure sensor has both advantages and disadvantages. On the one hand, it enables precise measurement of pressure, whether in air, water or other liquids or gases. What's more, it's easy to install and can be used in a wide variety of situations. However, it can also be costly and require regular maintenance to ensure proper operation. In short, despite its drawbacks, the pressure sensor remains an important tool for many industrial and technological applications. It is therefore advisable to carefully assess your needs before making a choice.