Variable speed drives are widely used in many industrial sectors. They offer many advantages, such as the ability to control the speed of an electric motor and thus optimize energy consumption. However, they also have certain disadvantages, such as high cost and complex installation. Variable speed drives are indispensable tools for improving energy efficiency, but their use requires careful study.

Automatic transmissions for better or worse

[arve url="https://www.youtube.com/embed/Cg2w6AWASTo "/]

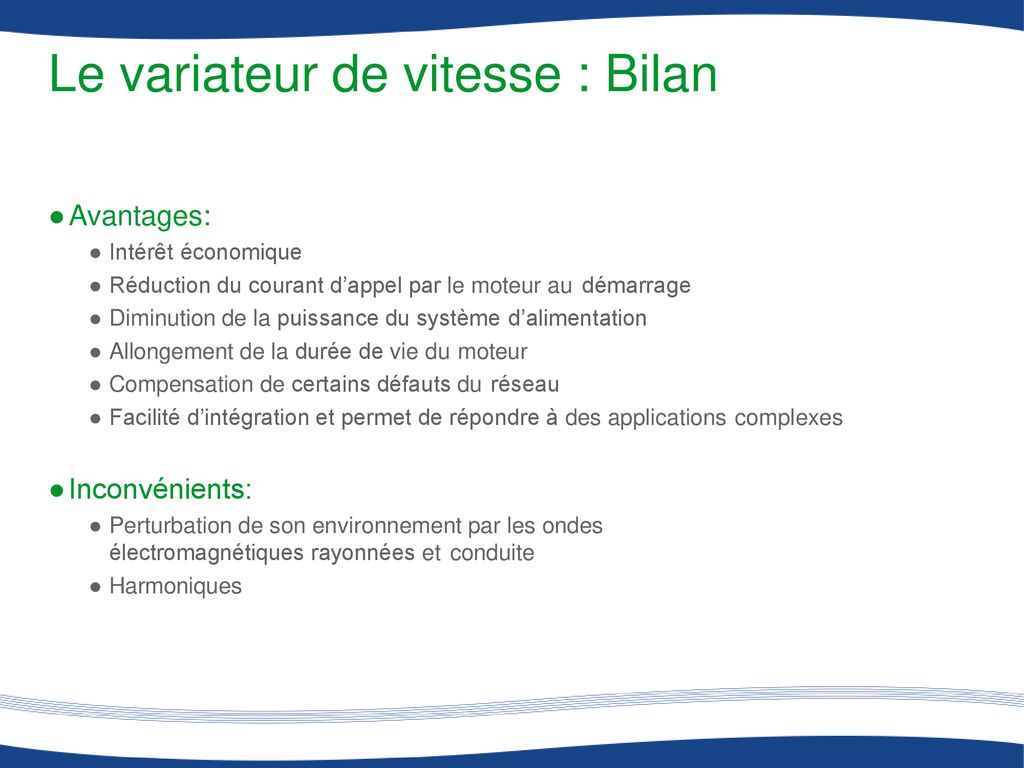

What are the advantages of variable speed drives?

The variable speed drive is a device for controlling the speed of an electric motor. It offers many advantages in different industrial contexts. Here are some of the main advantages of variable speed drives:

1. Energy saving : One of the main advantages of variable speed drives is that they enable significant energy savings. By adjusting the speed of the motor to the actual needs of the application, the variable speed drive limits electricity consumption and therefore reduces energy costs.

2. Precise control : The variable speed drive offers precise control over motor speed. It enables the speed to be adjusted progressively and maintained at a constant speed with great precision. This optimizes application performance and improves product or process quality.

3. Shock and damage reduction : By enabling the motor to start and stop progressively, the variable speed drive helps reduce shock and damage to equipment or products. This extends machine life and reduces repair or replacement costs.

4. Flexibility : The variable speed drive offers great flexibility, allowing the motor speed to be changed at any time. This makes it easy to adapt the application to specific requirements, be they load, production capacity or other parameters. It also enables effective management of load or process variations.

5. Noise reduction : By adjusting the motor speed, the drive helps reduce the noise level generated by the application. This improves working conditions and reduces noise pollution for operators and the environment.

In conclusion, variable speed drives offer numerous advantages, both economically and technically. In particular, they save energy, optimize performance, reduce shock and damage, offer greater flexibility and reduce noise. Its use is therefore essential in many industrial sectors.

What is the role of the variable speed drive?

The role of the variable speed drive is to control rotation speed an electric motor or other mechanical device. It allows the speed to be adjusted according to the specific needs of the application. Variable speed drives are widely used in various sectors such as industry, transport, renewable energy, etc. By modifying the frequency of the motor's power supply or adjusting the voltage, the inverter can regulate the desired speed. This offers great flexibility, optimizing performance, saving energy and extending equipment life. Thanks to its advanced technology, the variable speed drive has a significant impact on the overall efficiency of mechanical systems, and contributes to better resource management.

Why use a variable speed drive to regulate the speed of an elevator?

A variable speed drive is an essential element for regulating the speed of an elevator. It controls the power supplied to the elevator motor, enabling the car's travel speed to be precisely adjusted in real time.

The benefits of a variable speed drive in an elevator are manifold. First of all, it offers significant reduction in energy consumption. By adapting motor power to cabin load and traffic conditions, the drive optimizes the elevator's energy efficiency.

Secondly, the drive contributes to improve passenger comfort and safety. It smoothly regulates cabin acceleration and deceleration, avoiding jerks and jolts that can be unpleasant or even dangerous for passengers.

What's more, the drive offers greater flexibility in traffic management. Thanks to its advanced features, it can adapt to variations in demand and passenger flow, optimizing waiting times and journeys.

In short, using a variable speed drive to regulate elevator speed offers many advantages, such as reduced energy consumption, improved passenger comfort and safety, and better traffic management.

What types of variable speed drives are available?

There are different types of variable speed drives used in a variety of industrial applications. Here are some of the main types:

1. Variable frequency drives : these devices are also known as vector-controlled variable speed drives. They control motor speed by adjusting the frequency of the power supply. Frequency inverters are widely used in the industrial automation and machine control sectors.

2. Electronic drives : these drives use electronic components to regulate motor speed. They offer high control accuracy and are commonly used in applications requiring fine speed control, such as industrial robots and machine tools.

3. Mechanical drives : these drives use mechanical systems to adjust motor speed. They are generally used in applications where electronic control is not necessary or possible, such as automotive transmissions.

4. Hydraulic drives : these drives use hydraulic systems to control motor speed. They are commonly used in applications requiring high power output, such as cranes and construction machinery.

5. Pneumatic drives : these drives use compressed air to regulate motor speed. They are often used in industrial applications where an explosive atmosphere is present, as they avoid the risk of electric sparking.

These different types of variable speed drives offer flexibility and adaptability in motor speed control, helping to optimize the performance and energy efficiency of industrial systems.

In conclusion, variable speed drives offer numerous advantages for industrial applications. They save energy, extend equipment life and reduce maintenance costs. What's more, they offer great flexibility and precision in motor speed control. However, there are a few potential drawbacks. Variable speed drives can be expensive to purchase and install, require specific training to use correctly, and can generate electromagnetic interference. Despite these drawbacks, the advantages of variable speed drives make them an attractive choice for many companies. They add real value by improving energy efficiency and productivity. It is therefore important to carefully assess the needs and constraints of each application before deciding to use a variable speed drive.